Dirty Oil Detector

Lubricating oils and cooling oils play such a crucial role in the smooth operation of formers.

Oil deteriorating or clogging pipes due to contamination of foreign matters could lead to seizing because of not securing of the required amount of oil supply. However, you cannot tell how dirty the oil is by its appearance and period of use. Also, it is costly and such a time-consuming process to ask a testing institution to analyze the oil.

To overcome this situation, we, Sakamura, has developed the device that permeate-analyzes and quantifies the pollution level of oil and uses the numerical value to grasp the timing of oil replacement, named “Dirty Oil Detector (DOD).” With this device, oil contamination can be detected in JUST 10 minutes in-factory, and it lets you know when to refill or replace new oil.

Oil deteriorating or clogging pipes due to contamination of foreign matters could lead to seizing because of not securing of the required amount of oil supply. However, you cannot tell how dirty the oil is by its appearance and period of use. Also, it is costly and such a time-consuming process to ask a testing institution to analyze the oil.

To overcome this situation, we, Sakamura, has developed the device that permeate-analyzes and quantifies the pollution level of oil and uses the numerical value to grasp the timing of oil replacement, named “Dirty Oil Detector (DOD).” With this device, oil contamination can be detected in JUST 10 minutes in-factory, and it lets you know when to refill or replace new oil.

1.Collect current oil

The oil should be collected from the part circulating in the oil tank of the operating former.

Avoid bubbling areas as air bubbles can be falsely detected as dirt.

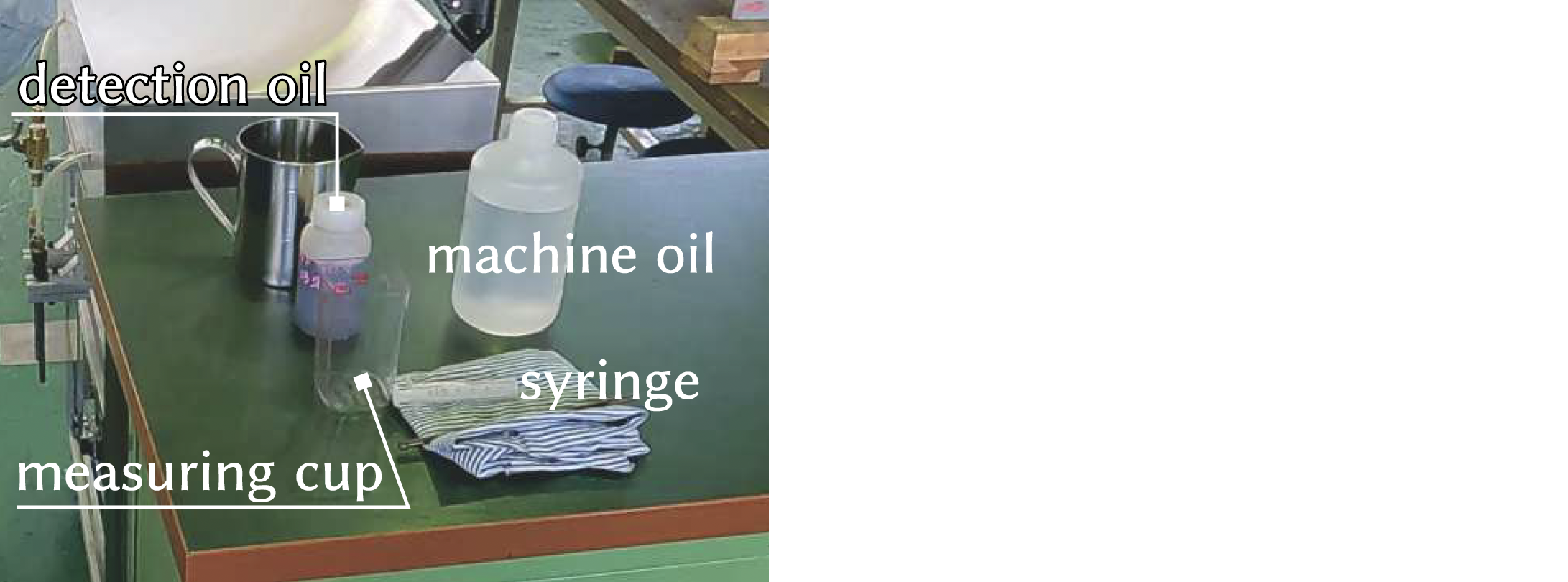

2.Prepare detection oil liquid

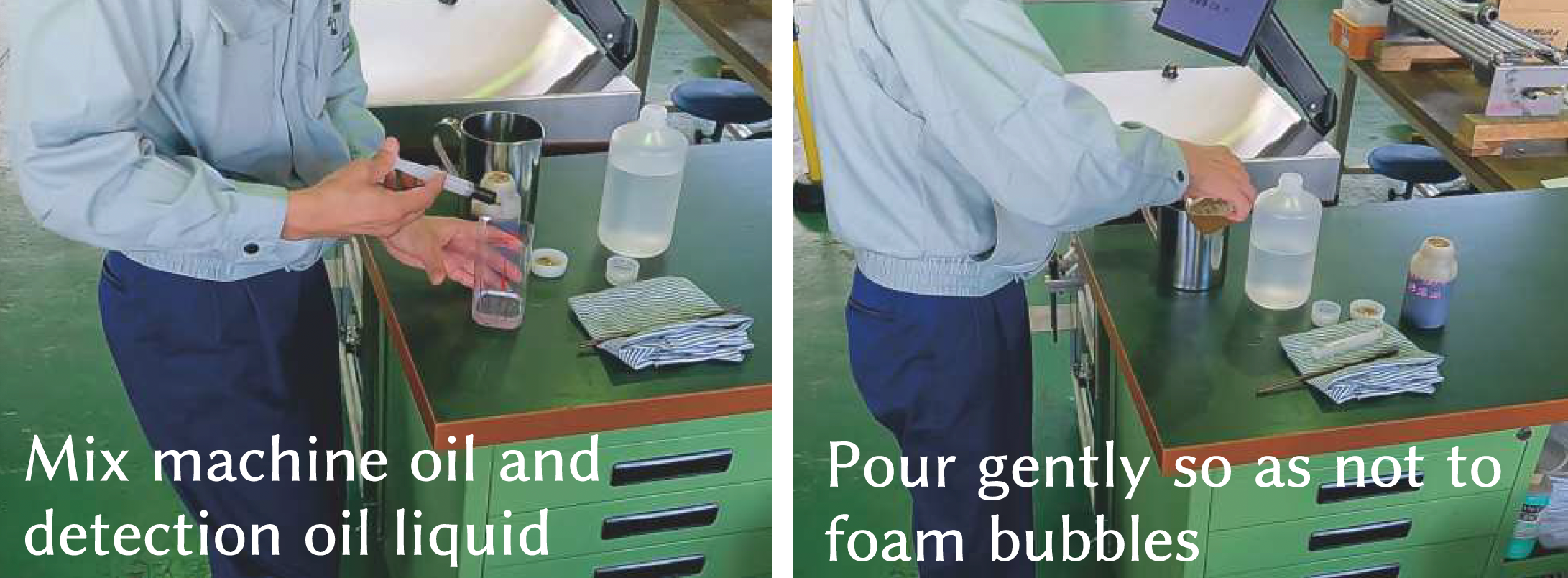

The sample should be made by mixing machine oil and current collected oil.

The current collected oil should be gently injected into the machine oil using the syringe and stirred so that it does not foam bubbles.

After stirring, gently pour into the detection container.

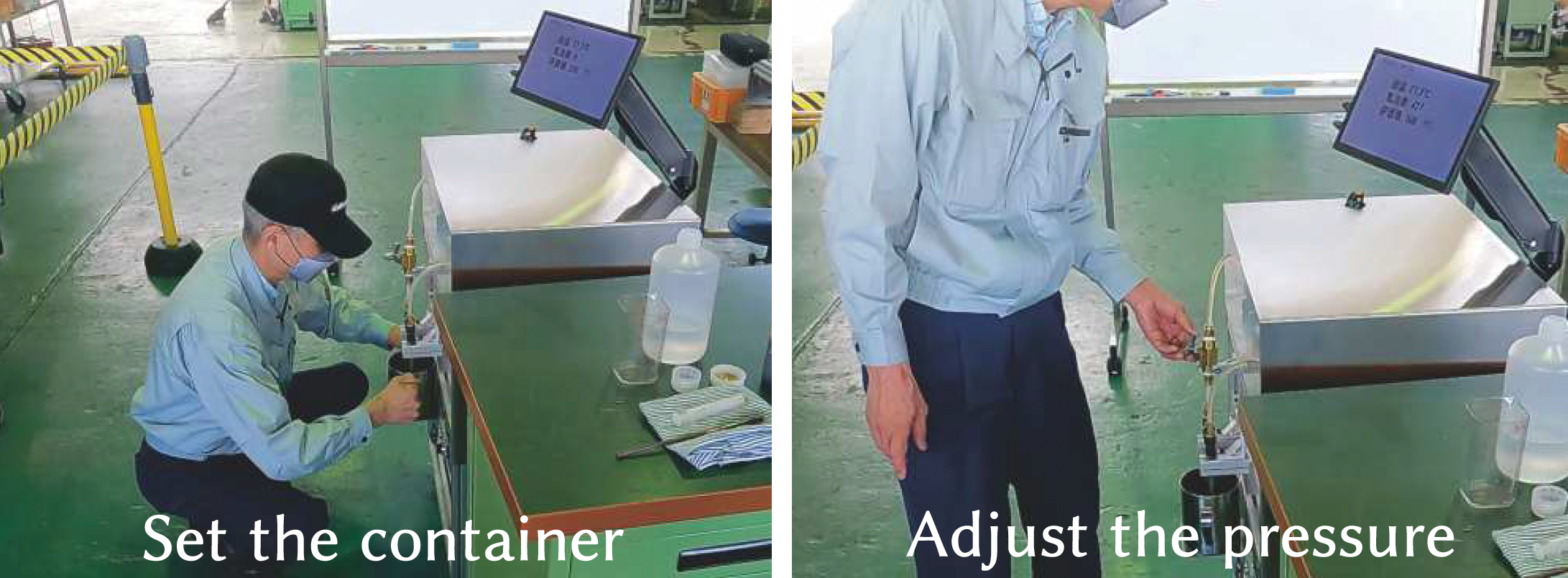

3.Detect pollution level

Set the container in DOD and start detection.

Firstly, activate the detection pump to stir the oil and adjust the pressure in the meantime.

Detection is ready when the number of bubbles becomes stable and constant.

- 650 or less : Contamination has started. Clean the centrifuge more often.

- 600 or less : The oil has been getting contaminated. Refuel the new oil and plan oil change.

- 550 or less : Contamination is severe. Change the oil as soon as possible to prevent clogging of pipes.

Please contact us for details.

Technology Information:Focus on Safety and Environment