Solution

Stable Operation

Two centrifuges are installed, one in the coolant tank and one in the lubrication oil tank.

The short feed cutoff device is similar to the LWM, but it only uses one channel to detect short feeds.

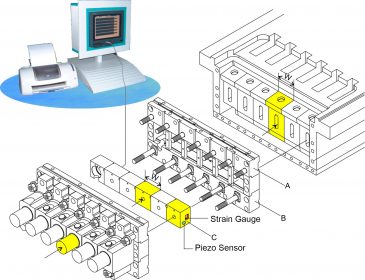

The forging load that is applied to the tooling is displayed in a waveform, even during setup. The LWM is effective in preventing damage to expensive tooling in large formers and for slight adjustments.

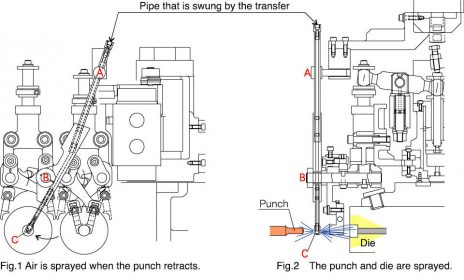

When the punch retracts, “C” uses spindle “B” as a drive source. Fulcrum “A” is set on the transfer and moves “C” to the front of the dies.

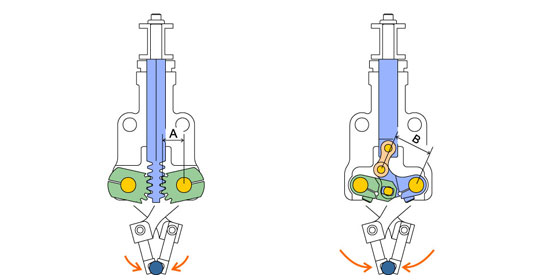

The rack and pinion system chucks have gear backlash, and the grip is weak.

The lever “knuckle” chuck has little backlash. In addition, as a result of the knuckle having more leverage by being twice as long as the rack and pinion style, the grip is stronger.

The lever “knuckle” chuck has little backlash. In addition, as a result of the knuckle having more leverage by being twice as long as the rack and pinion style, the grip is stronger.

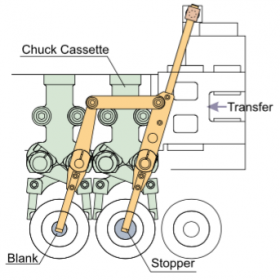

The simple PFAS (short parts stopper) was developed to assist the transfer when chucking becomes difficult (shoulder parts, short parts, etc.) during forging.